SCRAP CLEANING PLANTS

Scrap cleaning machines and metal sorting lines for ferrous and non-ferrous materials

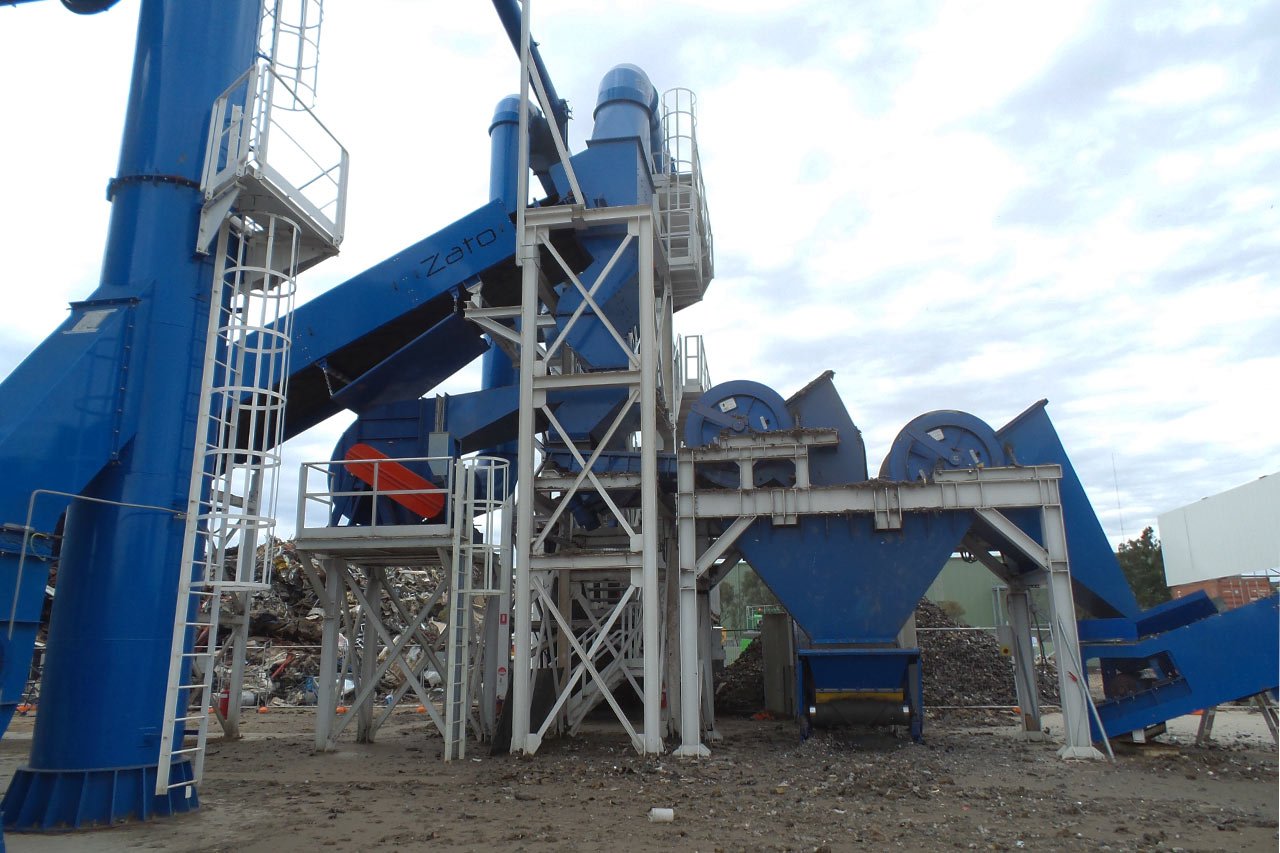

Blue Sorter scrap cleaning plants are manufactured with a high attention to detail. The use of scrap cleaning plants, which operate downstream of the shredding process, is crucial in the process of scrap recycling and the release of impurities. If the shredding ensures optimal size definition, the downstream process allows efficient separation of the different metals and residues, increasing the added value of the processed material.

Scrap cleaning plants are ideal for separating:

How do Blue Sorter scrap cleaning plants work?

The scrap cleaning process starts with the separation of light residues (light plastics, foam, wood and textiles) from heavy residues (metals). The magnetic separator system, which may include magnetic drums and belts, guarantees effective recycling of both small and large-sized ferrous fraction. Blue Sorter plants are designed and customised according to specific production requirements. This allows high levels of customisation and the best results in both recovery and purity of scrap metal.

Separation of ferrous and non-ferrous metals

We produce high-quality scrap sorting plants capable of effectively separating non-ferrous metals from each other. Aluminium, copper, brass, stainless steel and all other non-ferrous metals are not influenced to the magnetic separator of the Blue Sorter. To separate metals we use a variety of technologies: Eddy Current separators, induction sensor selectors, X-ray separators.

Need more information?

Fill the form below, we will reply as soon as possible!